By Elizabeth Ritch (GreenBlue)

With contributions from Jennifer Foreman (ExxonMobil) and Shannon Cousineau (NSF)

Ingredient Review for Safer Choice

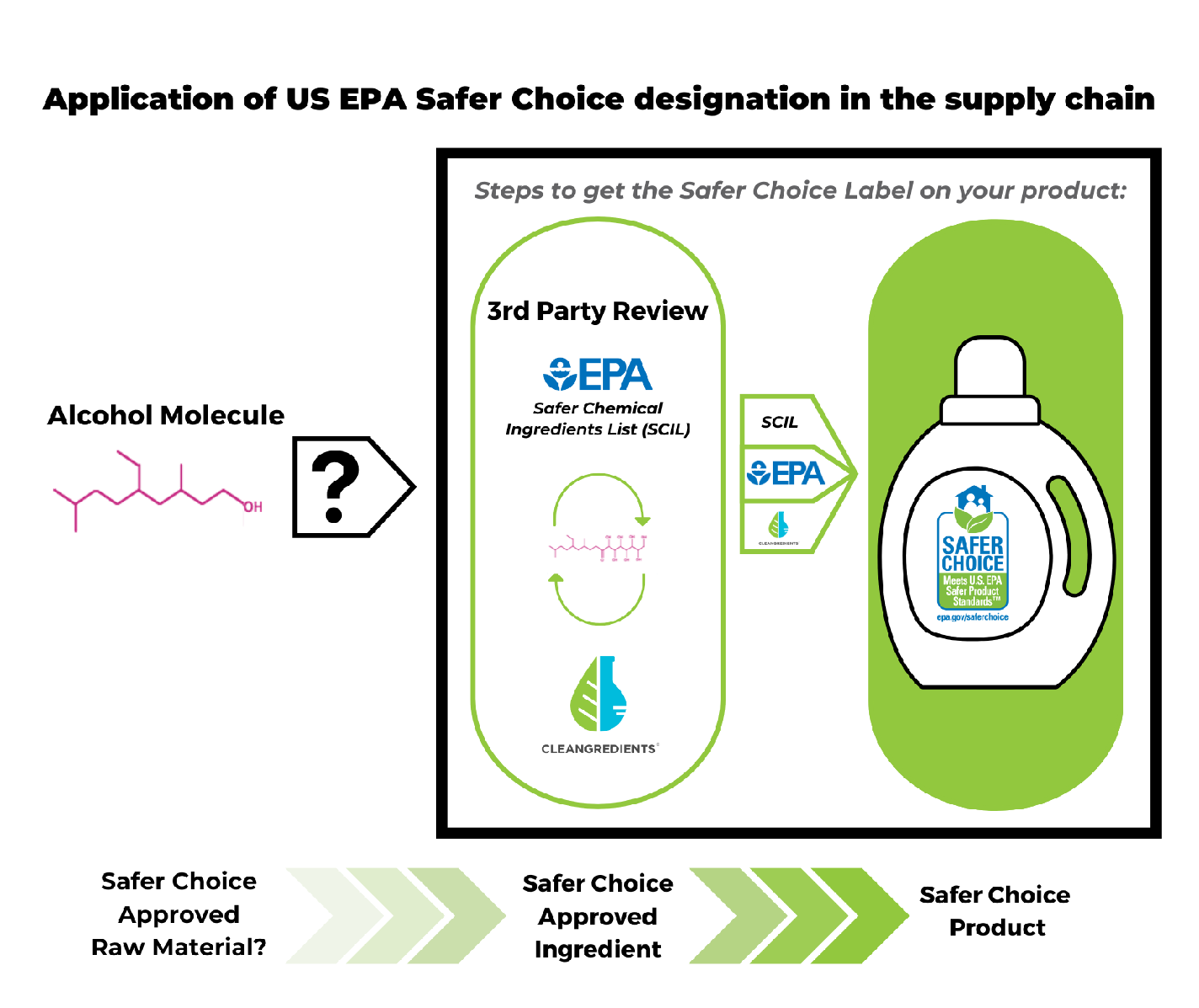

EPA’s Safer Choice certification program was created to help consumers and businesses identify products made with safer chemical ingredients. One of the unique aspects of the program is that it requires all intentionally added ingredients, as well as non-intentionally-added substances present above a de minimis threshold level, to be assessed against human and environmental health criteria, such as carcinogenicity, reproductive/developmental toxicity, toxicity to aquatic life, and persistence in the environment. Because it takes a scientifically robust approach to recognize products that are among the safest in their categories, the Safer Choice program has received support from stakeholders including industry, environmental NGOs, and consumer advocates.

When a company wants to pursue Safer Choice certification for a product, they must disclose all ingredients contained in the product, along with their suppliers, to their third-party profiler. The third-party profiler then assesses all chemicals present in the ingredients against the relevant Safer Choice criteria. If additional information is required – for example, for trade-name ingredients containing proprietary chemicals – the third-party profiler will contact suppliers directly to get necessary information. Depending on the chemistry in question, as well as the structure of the supply chain, the profilers may need to reach out to those suppliers’ suppliers, and so on, until they are able to obtain all of the data necessary to complete their review.

CleanGredients Streamlines the Review Process

Many suppliers with ingredients meeting the Safer Choice criteria supply those materials to multiple product formulators, who in turn may use them in various product formulations that are ultimately submitted for Safer Choice review. Reviewing these ingredients multiple times on behalf of different product formulators would make the review process more time consuming and costly. Plus, it benefits product formulators to know earlier in the product development process whether an ingredient will meet Safer Choice criteria.

This is where CleanGredients comes in. Ingredient suppliers work directly with third-party profilers and Safer Choice to verify that their trade name ingredients meet Safer Choice criteria for their functional class. Since it launched in 2006, CleanGredients has grown to list over 800 pre-approved trade name ingredients, helping streamline the Safer Choice certification process for numerous formulators.

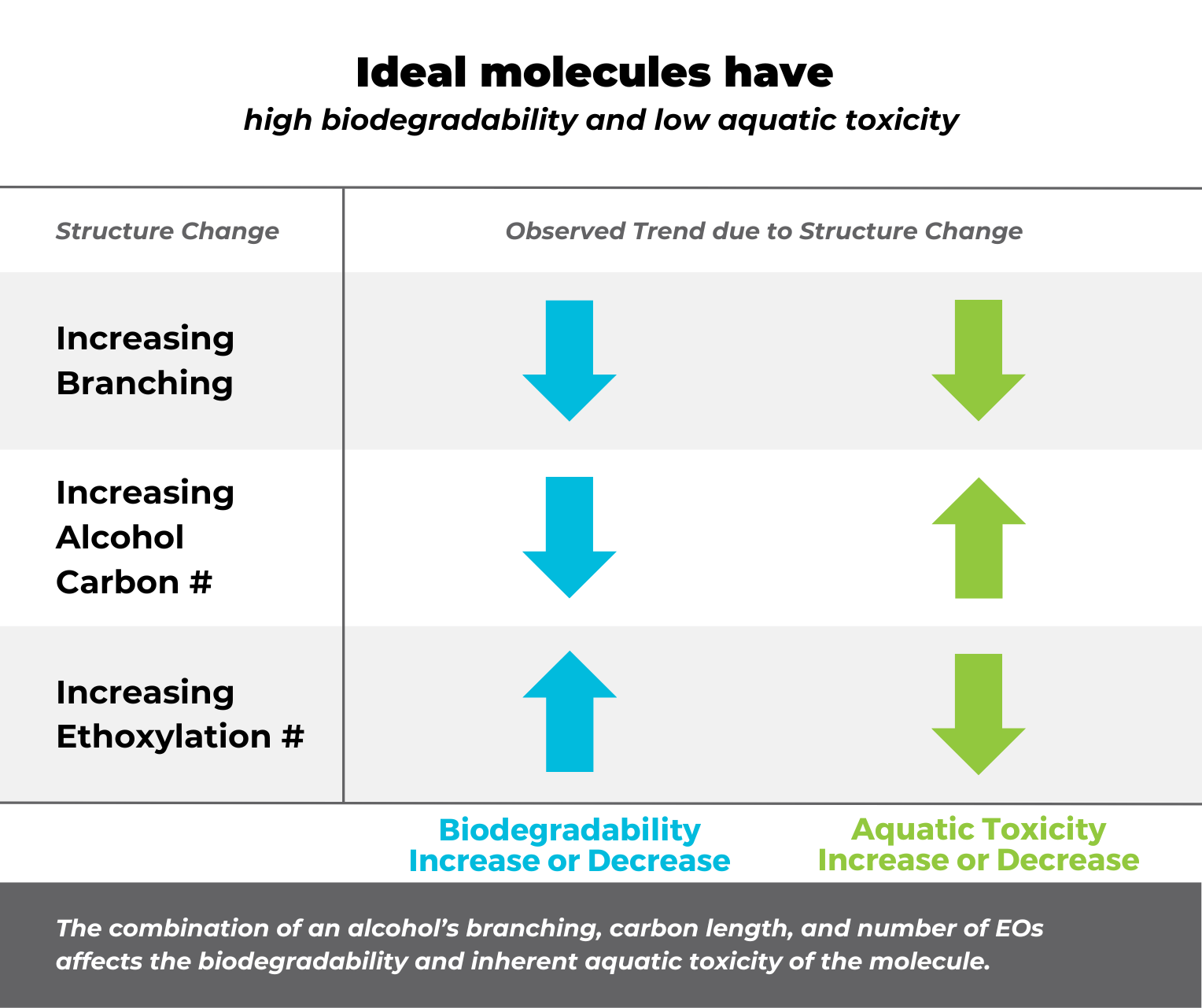

CleanGredients is not the only resource that identifies chemicals meeting Safer Choice criteria. The Safer Chemical Ingredients List (SCIL) maintained by EPA also identifies chemicals, by functional class, that meet the criteria of the Safer Choice program. Unlike CleanGredients, the chemicals listed in SCIL are not trade name materials supplied by specific manufacturers, but are identified by chemical name and CAS number. While SCIL is a valuable resource for identification of safer chemical alternatives, additional information may be needed to determine whether a particular ingredient sold by a particular company will meet Safer Choice criteria. Many CAS numbers represent chemicals with variable characteristics, and not all instances of these chemicals meet Safer Choice criteria. One example is branched alcohol ethoxylate surfactants, where factors such as chain length and degree of ethoxylation affect the aquatic toxicity and rate of biodegradation. This means that even among the structures characterized by the same CAS number, not all will meet the Safer Choice surfactants criteria, including the more stringent criteria for products that are used outdoors and released directly into the environment.

The review process to list an ingredient in CleanGredients addresses these concerns, since specific data for the trade name ingredient is considered by third-party profilers. However, the process to obtain this data is not always efficient, especially when supply chains are not vertically integrated, and third-party profilers need to make contact with higher level suppliers to get the information they need. The time it takes for a request for data to filter through the procurement team and make its way to the regulatory team that can supply the appropriate data can lead to confusion and longer review periods.

A Proactive Approach to Data Creation Higher Up the Supply Chain

ExxonMobil is the higher-level supplier for many of the precursor alcohols that are used to create the alcohol ethoxylate surfactants in many Safer Choice-certified products and CleanGredients-listed ingredients. ExxonMobil was asked by numerous customers to provide data on its precursor alcohols in support of CleanGredients or Safer Choice review. These requests came in piecemeal, and the data needed for the review process was not always clear. So, the company started to consider whether a proactive approach to generating data might help them better support customer requests and be able to market its Exxal™ product line as a safer chemistry solution.

It was not immediately clear how review of the Exxal™ products fit within the existing Safer Choice review framework. (Graphic adapted from Jennifer Foreman, ExxonMobil)

Because the Exxal™ products constitute such a large percentage and have a heavy influence on the properties of the resulting surfactant, they have a significant influence on whether surfactants made from them will meet Safer Choice criteria. In addition, the variability of ingredients in this product category means that surfactant manufacturers can’t simply rely on SCIL to ensure their ingredients qualify for Safer Choice – they need to obtain much more nuanced information from their suppliers or generate additional data themselves. Because of these factors, a better understanding of how the Exxal™-based ethoxylates align with Safer Choice criteria had the potential to be very helpful for both ExxonMobil and its customers. The degree of branching of the base alcohol is another key factor that affects the aquatic toxicity and rate of biodegradation of the ethoxylated derivative. Whereas the structural aspects of the ethylene oxide molecule do not change regardless of supply, the degree of branching is unique to the different trade name alcohols. For example, any surfactant producer that derivatizes an Exxal™ alcohol can expect the same environmental performance for the resulting product, the reverse is not the case for the supplied alcohol. If a surfactant producer were to change their alcohol supplier, the subsequent derivative would no longer have the same environmental profile and any Safer Choice designation would not be guaranteed due to the impacts of alcohol’s structure on test performance. By providing specific data for their trade name alcohol, ExxonMobil is able to provide a guarantee as to which derivatives based on their molecules will meet the Safer Choice criteria, including the more stringent direct release criteria.

(Graphic adapted from Jennifer Foreman, ExxonMobil)

ExxonMobil chose to work with NSF, one of the third-party profilers qualified to assess both ingredients and formulated products against the Safer Choice program’s criteria. Because the products being assessed were not direct ingredients in finished products eligible for certification, the assessment process was a little bit different, and NSF and ExxonMobil had to determine what data would be required to appropriately evaluate the suitability of each Exxal™ product for Safer Choice applications.

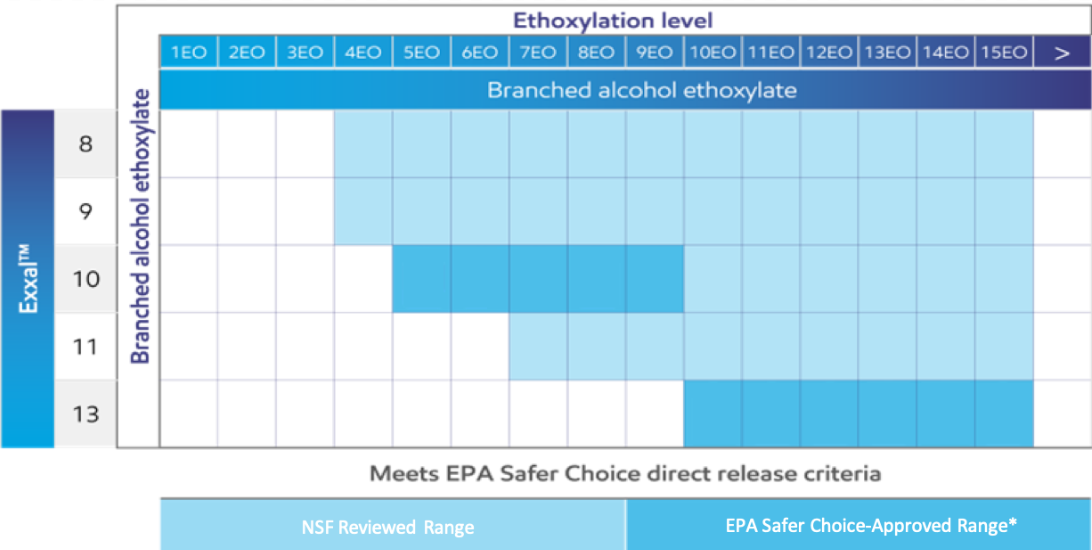

ExxonMobil chose to put together a broad data set for the entire family of Exxal™ alcohols. One advantage of this approach was that taking a broader perspective made it easier to interpolate, rather than requiring separate data for every single molecule. After working with NSF to generate relevant data for the products in the Exxal™ family, NSF and ExxonMobil consulted with EPA to narrow down additional questions that needed to be answered. In this way, they were able to ensure that EPA had the data necessary to understand the hazard profile of the chemistries being assessed and the surfactants derived from them, while minimizing any unnecessary animal testing.

In their work with EPA, NSF and ExxonMobil learned that EPA required a greater degree of data coverage and enhanced model validation than initially anticipated, especially for a direct release designation addressing releases directly into the environment. EPA and ExxonMobil environmental toxicologists were able to agree on a testing plan which would provide adequate coverage for the remaining substances. This testing is now underway and once complete will provide a complete picture of Exxal™ based ethoxylated derivatives and how they meet the Safer Choice Criteria.

EPA data requirements meant a narrower range of Exxal™ derivatives were confirmed to meet the Safer Choice criteria. (Graphic provided by Jennifer Foreman, ExxonMobil)

The path ExxonMobil chose presents a good example for other suppliers of “precursor” chemicals that are sold into applications used in Safer Choice products, especially those that have a heavy influence on the human and environmental health attributes of the “ingredient”-level chemicals made from them. By working with a trusted third-party profiler to generate a complete set of data, and collaborating with EPA to ensure that the right questions are being asked, chemical manufacturers can reduce uncertainty for their customers who are trying to create products, such as surfactants, that will meet the Safer Choice criteria.

Safer Choice certification for finished products helps end users easily select safer options for human and environmental health. CleanGredients helps product formulators easily select ingredients meeting the Safer Choice criteria for human and environmental health. This new model of proactive assessment of precursor chemicals serves the same function for ingredient suppliers, ultimately making it simpler, faster, and less risky to bring safer chemistries to market.

Sharing Information Through the Safer Choice Community

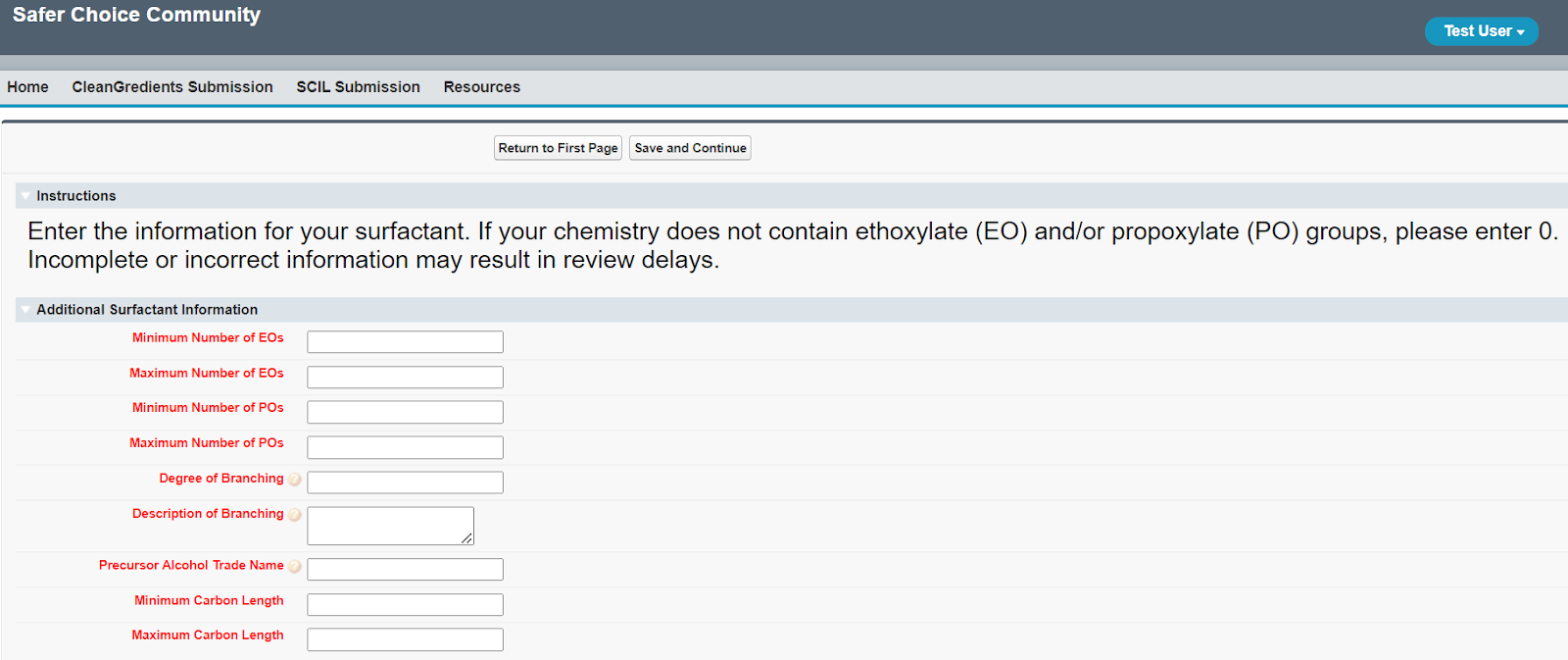

Because the assessments of the Exxal™ products fall outside of the scope of either Safer Choice-certified products or ingredient-level chemicals eligible for CleanGredients listing, a new way to share data was needed. To accommodate this, EPA has been working to pilot additional data fields within the Safer Choice Community which will allow third-party profilers to see the precursor or starting materials for ingredients, reducing the need for follow-up information requests. Plans to create new generic “ingredient” listings within the Safer Choice Community for Exxal™-derived surfactants are under development, so that third-party profilers will not be required to perform unnecessary additional reviews, and reviews will be consistent across all third-party profilers. Eventually, if more suppliers of precursor chemicals follow this path, there could be opportunities for more public listing of assessment results, much like the way CleanGredients currently functions for ingredient-level chemicals.

EPA is working to pilot additional data fields in the Safer Choice Community that will enable sharing of key data on surfactant precursors to streamline the review process. (Graphic provided by EPA Safer Choice)

Future Potential

In the long run, this proactive approach to creation and sharing of human and environmental health data stands to benefit the entire supply chain. One of the biggest challenges in bringing verified safer products to market has been the availability, and generation cost, of the necessary data to ensure that the chemicals in use are truly safer for humans and the environment. Platforms for sharing data, including SCIL and CleanGredients, have made great strides in reducing cost and uncertainty for product formulators, but precursor chemicals, such as the Exxal™ alcohol product family, do not fit neatly within this structure. Ultimately, enabling data sharing from higher level suppliers will make it easier to identify chemistries that will meet Safer Choice criteria, enabling innovation and creating efficiencies and certainty for the whole supply chain. This has the potential to benefit the Safer Choice program as a whole, by making the review process faster and more certain for more chemistries, while maintaining the integrity of the Safer Choice review process.